Cars have many components that work together to help you get from start to finish, and one of the most important of them is the steering wheel. However, the steering wheel is not as simple as it looks. It is designed more as a final piece to the puzzle of a steering system to enable the car to turn. Integrated in the steering system is a timing belt, hoses, a pump, reservoir, fluid, pulleys, and a steering rack/pinion. If any one of these vital components fails or is not properly adjusted, then your steering system will either lack in performance or not work all together.

Steering Wheel

So why is my steering wheel hard to turn, you ask? To find out, it comes down to a matter of general knowledge and troubleshooting. Below will be a list of problems that can affect steering performance:

Low or Dirty Power Steering Fluid

Power Steering Reservoir with Fluid

One of the most common causes of a steering wheel being hard to turn is a low level of power steering fluid or the fluid being dirty. A low level of power steering fluid will usually tell on itself by the squealing sound it makes when the wheel is turned. Dirty fluid makes itself more known by steering feel and performance. One of the two (or both) will require extra force to be applied to the wheel to turn it. This can put major strain on the power steering pump, causing damage in the long run if left unchecked for too long and call for expensive repairs.

Luckily, this problem is one of the easiest to fix. For around $5-$7, you can buy power steering fluid and refill your reservoir and restore your vehicle’s steering functionality. Power steering fluid can be bought from auto stores like Autozone, O’reilly Auto Parts, Advance Auto, and even stores like Lowe’s and sometimes 7-Eleven. Make sure the power steering fluid you buy is compatible with your vehicle’s make and engine type to ensure no further issues happen. It’s always a good practice to purchase vehicle specific fluid instead of universal, but if you’re in a pinch and really in need of fluid, then the universal brand should satisfy your needs just fine.

Fill the reservoir to the upper level. Do not overfill to prevent spilling underneath the cap because the fluid volume rises once the engine is on. By chance, if you have run completely dry of power steering fluid, then overfilling the reservoir is actually the best thing to do because the system is going to feed all the fluid from it until enough is in the system (About 3 bottles are recommended for this procedure). In this case, the system will usually need to be bled of air at the same time. Doing so is simple. By turning the wheel all the way from one side to the other and holding it for a few seconds between each turn allows for air to be forced out.

This will likely need to be done for a minute or two. The disappearance of bubbles and fluid retention in the reservoir are indications of a successful bleed/refill. Be sure to double check your fluid level after the process.

Worn Out or Leaking Power Steering Hoses

Power Steering Pressure Hoses (High[R]/Low[B])

There are two hoses that cycle fluid between the power steering pump: The high pressure hose and low pressure hose. For $9-$17, a replacement low pressure hose can be bought and installed. A high pressure hose can be replaced for around $45-$55. These hoses can be purchased from your local auto store either same-day or store-ordered. Both of these replacement estimates are based on DIY procedures (expense of tools not included).

Check for signs of wear, leaks, and loose hose clamps in and under the engine bay. Worn hoses are not too difficult to spot. Old and possibly cracked hoses are signs for replacement, but don’t let loose hose clamps on the low pressure hose fool you into thinking your hose needs to be replaced. When in reality, it just needs to be adjusted. This can be done simply with a pair of pliers.

Grip the two ends of a clamp to expand it and slide it up or down the hose. It’s best to fasten the clamp just a little below the end of the hose to prevent the hose from possibly slipping back from under the clamp and causing a leak. Hose clamps are placed at both ends of each hose. So make sure to check both ends of each for proper adjustments.

Only the low pressure hose has clamps. The high pressure hose is secured to the top of the power steering pump by two bolts, leading down to the steering rack. Checking the bolts at the head that connects to the steering pump is a good idea before moving down the list of troubleshooting steps. Scan the hose in its entire length as best as possible to ensure acceptable condition. Removing this hose actually requires going under the vehicle to disconnect it, so if you aren’t up for that task, take it to a shop and let the auto technicians handle it.

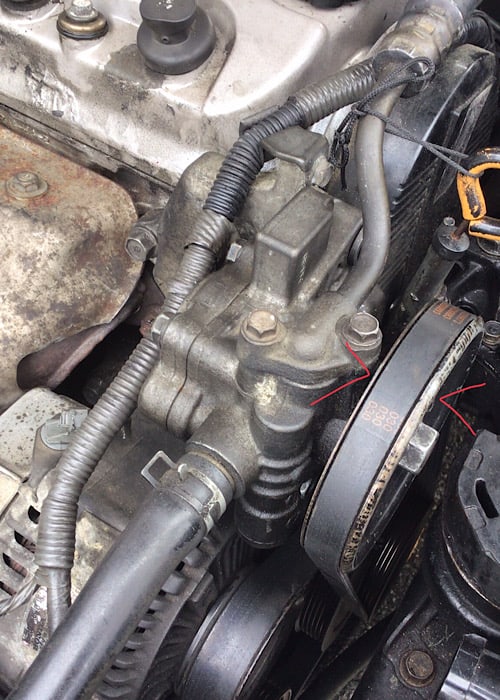

Old or Loose Power Steering Belt

Power Steering Belt

A more complex issue to fix in the steering system is the power steering belt. The power steering belt supplies power to the pulley to make steering easier. If the belt is cracked, nicked, missing grooves, worn (dry and dull appearance), or past due for replacement, the steering wheel will be hard to turn. A telltale sign that the belt is the cause of your trouble is loud squealing or squeaking sounds from under the hood when you turn the wheel or the car is idling (The power steering pump and pulley will also shake intensely if the belt is too loose). Fortunately, the cost for a DIY replacement of a power steering belt is not too expensive.

A replacement belt can be bought for around $14-$16 from your local auto stores (expense of tools not included). If your belt is not worn and is just loose, the correct amount of tension needs to be applied to your belt. Achieving this could be as simple as loosening a couple bolts and pulling the power steering pump forward. Only two bolts that support tension being undone is enough to dismount the pump for up and down movements (only). Accomplishing this task requires a pry bar, ¼ drive ratchet, a ⅜ drive ratchet, and a full socket set.

A serpentine belt tool can be used, but it’s completely optional. The pry bar comes into play when applying more tension. Wedging it behind the pump (while the belt is connected to the pulley) to find the right tension point eases the trouble of trying to pull the pump forward by hand while tightening the belt. Remember, the tighter the belt, the better your steering wheel will perform, but don’t over tighten it because it will cause premature wear of the belt and affect mileage span.

In the event that the belt actually needs replacement, then simply undoing the two bolts for tension is enough to slip the old belt off the power steering pulley and the harmonic balancer to get a new one on. Install the new belt by placing it around the harmonic balancer, then the power steering pulley. Once that’s done, position the power steering pump at the angle that gives desired tension to the belt and tighten the tensioner bolts back in place. Start the car and turn the steering wheel to listen for any loud, unusual sounds that may indicate the belt is not tight enough. If everything is done correctly, then you should hear no noise from the hood other than a slight squeak that new belts tend to make sometimes.

It usually subsides quickly if it does happen, so it’s nothing to worry about. Check this video out to use as a step-by-step guide for a power steering belt replacement.

Bad Power Steering Pump Pulley

Power Steering Pulley (Circular Wheel)

The power steering pump pulley is what the power steering belt connects to and enables power steering. These two together help give power to the pump and cycle the fluid. A failing pulley will create belt tension issues, disable power steering, and make the steering wheel hard to turn or stop steering all together. Symptoms to check for with pulley issues would be:

- Burning smell

- Rigid steering

- Complete steering failure

An estimated cost for a pulley replacement (part only) ranges between $25-$80. Expect to spend more than $100 if doing a full DIY procedure when you consider the expense of tools. Paying for a professional replacement will range between $180-$250. The replacement of a power steering pulley for a Honda doesn’t involve using a special pulley puller/installer kit like Fords, Chrysler’s, GM’s, and Volkswagens do.

To remove the pulley, a ratchet, something to hold the pulley in place while torque is applied to the bolt (because the pulley rotates with the bolt), and leverage will do the trick. The pulley should slide right off the shaft after the bolt is taken out, allowing for installation of a new one. Keep in mind that doing this involves taking the power steering belt off and having to put it back on and adjusting tension later.

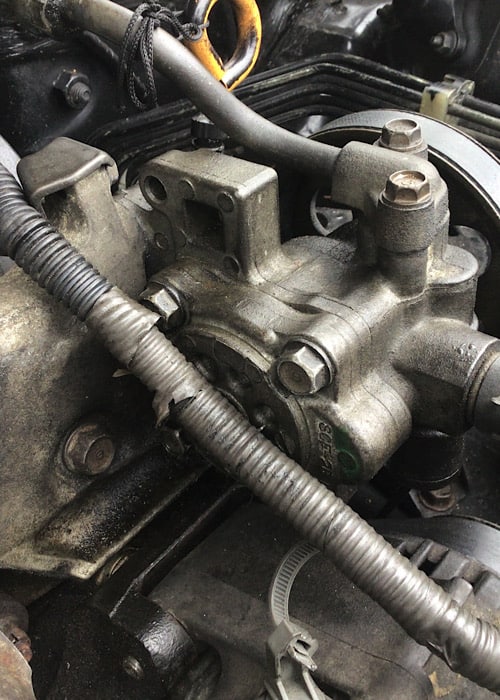

Bad Power Steering Pump

Power Steering Pump

In a hydraulic power steering set up, the power steering pump distributes power steering fluid to the system to enable movement with less force and assist with steering. The fluid regulates under pressure and transfers power to the steering gear, which amplifies effort and makes steering so easy. Without this pump, power steering is completely impossible. The symptoms to be aware of with a bad or failing power steering pump are:

- Strained steering

- Noticeable pump vibration

- Noise when turning the wheel

- Noise under the hood

A power steering pump replacement is on the more expensive side among the rest. For $132-$245, a replacement pump can be bought. Basic hand tools like a ratchet and socket set are all that is needed for this job because it is relatively simple. If you are not a DIY, then expect to spend somewhere around $500-$800 all together at a shop.

To remove the power steering pump, a number of bolts need to be undone (Namely, the two tensioner bolts that give the serpentine belt its tension). Once unfastened and the belt is placed to the side, the low pressure return hose can be removed. Make sure to have a small container to catch fluid that will run when the hose is disconnected and something to cover the alternator below to avoid a mess. With that off to the side, the head of the high pressure hose can be removed next. Undo the two bolts that secure the line to the pump and expect fluid spillage (This will allow for the hose to be sidelined until later).

Now that the serpentine belt and lines are out of the way, taking the pump itself off is the last step. Don’t confuse the set of four bolts on the side of the pump for bolts that need to be undone. These are the bolts to the gasket, which hold fluid in the pump. Undoing these will only create a loss of steering fluid and a possible introduction of air into the system. There are four bolts in total (spaced out) that will completely dismount the pump when removed.

The hardest will be the awkwardly placed bolt at the bottom. Keep an extension piece nearby just in case with a set of gloves to protect your skin from damage, and don’t forget something to catch any extra fluid that may run from the pump. There isn’t much more to this job after you uninstall the pump other than installing a new one. Reattaching the hoses to the pump and the belt to the old or new pulley is all that’s left to call it a day.

Problems With Steering Rack and Pinion

Rack and Pinion System

The steering rack is what connects to the wheels to turn them left or right when the steering wheel is turned. Above the steering rack is the steering column or shaft that leads up to the steering wheel. A steering gear powered by the power steering fluid, sometimes referred to as a pinion, on the rack connects to the steering shaft and engages additional force to help with navigating the vehicle. The steering rack and pinion work in conjunction, so it goes without saying if either one of these fails, then the steering wheel will be hard to turn.

Symptoms of bad a steering rack and pinion include:

- Difficulty steering at low speeds

- Grinding noise when turning wheel

- Burning smell

- Fluid leak (steering rack area)

A DIY repair or replacement for the steering rack or pinion is commonly not recommended because it is the most difficult to perform of all on this list. Unless you are an experienced auto technician, then it would be best to let a professional handle it. However, if you still want to give it a shot, the cost for a replacement steering rack could cost as much as $726, depending on vehicle make and year. A pinion replacement is less costly at roughly $18. Having work done at a shop will vary from $1,400 to $1,800 because this is a very time-consuming job that consists of heavy labor but is also a safer option for ensuring the problem is properly corrected.

It all comes down to how much time and money is willing to be spent to get things back in the right condition. Again, this is a difficult job to perform that requires going under the steering wheel to access and release the steering shaft from the rack, removing tie rods, disconnecting the high pressure hose from the rack itself, and a lot more disassembly procedures that likely won’t be too inviting for the inexperienced or those who don’t have days to spare working on it. Here is a link to a YouTube video to show the difficulty level of the job and what to do.

Hopefully, this guide has helped to steer whoever is having trouble with their power steering in the right direction for solutions and repairs. Look through the RV Lifestyle vehicle guide if any other automotive wonders come to mind.

Jill Miller is the founder of Your RV Lifestyle. Trading corporate America for the open road, Jill, along with her partner Jose, began their RV journey, making an unconventional start by wintering in New Jersey. A natural adventurer, she was motivated by a desire to explore the USA and beyond, embracing the varied landscapes, communities, and cultures across the country.

For Jill, the allure of RV living was not about material accumulation, but rather the pursuit of an adventurous, fulfilling lifestyle. A lover of golf, bicycling, hiking, and line dancing, she has carried her passions across the country, engaging with them in diverse settings. Jill’s commitment to the RV lifestyle came after years of careful research, numerous consultations with RV owners, and personal trials, including living in a rental RV.